OVERVIEW

- MultiTech, Firm established in the year 2014. We provide the engineering support and manufacturing solution to critical applications, we are able to meet customer requirements with high dimensional accuracies and mechanical performances.

- Delivering the best quality products, that satisfies the present requirements of our Customer’s on time.

- And are able to be comprehensive ONE – STOP – SHOP solution providing firm.

- Certified with quality compliance ISO 9001 – 2015 certified.

- Machining Unit (unit-I)

- Foundry Unit ( Multitech Founders Unit – II)

- Manufacturing facility spread across 22,000 sq. ft. (Foundry & M/C Shop)

- Total manpower of 110 nos.

Why MultiTech

We are the engineering manufacturer solution, providing the highest quality products, services and solutions to our customers.

Core Value

SCOPE OF WORK

- To Manufacture and supply graded S.G Iron, Cast Iron, and Bar stock components in Precision Finish machined, Semi-finish machined condition, with ready to assemble condition and in sub-assemblies also.

- All manufacturing solution under one roof.

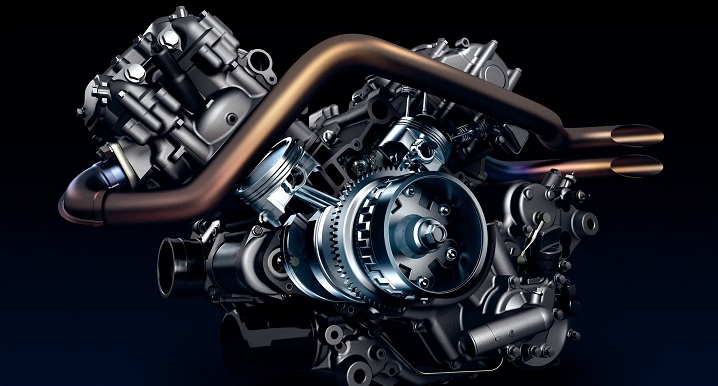

- We are catering to the various sectors like Material Handling, Infrastructure , Valve Industry, Transmission , Chiller and Compressor Components, Stationary Engines, Earth Moving (Excavators), Power generation, Agriculture Equipments, Automobile Industry, Automotive Industries, Hydraulics (Gear Plumps), Hydraulic Cylinders, etc.

- Engaged in supplies of assemblies and sub-assemblies as per customer requirement.

STRENTHS

- Small to large batch sizes.

- All molding process under one roof.

- Practice of TOC for overall business growth.ss

- Adequate infrastructure and in house manufacturing facilities.

- Faster response time.

- Dedicated development team.

- Strong sub contracting base.

- Sound financials.

- Full fledge in house testing facility.

Machining Division facility

Machine Division is a full fledged setup with latest Machining Centers (VMC), CNC turning Centers and VTL which production capacity range from 6” Chucking to 20” chucking capacity, with conventional machining centers, Milling Machine and set of drilling machines with SPM. All standard inspection facilities with CMM. The machining division runs in three shifts, with the built up area of 9000 Sq.Ft.

Foundry Manufacturing facility

Built up Area 13000 Sq ft, Production Capacity 125 MT per Month, Presently Utilized 45 MT per Month, Range of the Castings 0.150 Kg to 280.000 Kgs, Grades All grades of S.G. Iron and Gray Iron. Molding Process Green Sand, Sodium Silicate (CO2), No-Bake & Shell mould, Molding Method Tusker flask. Fix Box, Jolt Squeeze pin lift & Loose Flask Type, Core Process Sodium Silicate, No-Bake, shell, Melting 350 Kgs Induction Furnace with 350 kw panel, Surface Finish Shot Blast & Sand Blast machine, Pattern Out Source.

Grade Production facility

| Ductile Iron Grade | |||||

|---|---|---|---|---|---|

| Grade | Tensile Strength | Yield Strength | Elongation | ||

| ASTM | UNS | σ≥/Mpa | σ≥/Mpa | δ≥(%) | |

| 60-40-18 | F32800 | 414 | 276 | 18 | |

| 65-45-12 | F33100 | 448 | 310 | 12 | |

| 80-55-06 | F33800 | 552 | 379 | 6 | |

| 100-70-03 | F34800 | 689 | 483 | 3 | |

| Cast Iron Grade | |||||

|---|---|---|---|---|---|

| Grade | Tensile Strength | Hardness | |||

| ISO | σ≥/Mpa | σ≥BHN | |||

| FG 150 | 150 | 150 - 210 | |||

| FG 200 | 448 | 170 - 230 | |||

| FG 250 | 552 | 187 - 240 | |||

OUR POLICY

- We, at MULTITECH,

- will Strive to supply cost effective,

- consistent quality product

- & on time delivery

- by involving all our resources

- through continual

- improvement.

OUR VISION

- Provide the engineering Support &

- Manufacturing Solution

- to Critical Applications,

- Able to be Comprehensive

- ONE-STOP-SHOP

- Solution for Customer

- Satisfaction.

OUR QUALITY OBJECTIVES

- TO Involve and Empower

- all Employees

- Across the Organization

- to achieve Total Quality

- through providing

- Adequate Process

- Environment.

- Spectrometer with 21 elements

- Universal tensile testing machine (UTM).

- Brinnel Hardness Tester & Poldi Hardness Tester

- Metallurgical Microscope with image analyzer

- Mould Hardness Tester, Permeability Meter

- Green Compression Strength Tester

- Compactability Tester, Rapid Moisture Tester

- Shell sand and core testing equipments

- Carbon & Silicon Analyzer for on line testing of chemical composition

- All other tests will be done at reputed laboratories situated at Belgaum.

- Addition of molding tracks to increase the capacity.

- Addition of Horizontal machining centres.

- Addition of furnace with 500 Kgs. Capacity.

- Addition for component cleaning facility for precision application

- CNC turning machine Size 8” to 15” chucking capacity :- 8 nos.

- VTL Machining center with 1000 mm swing and 800mm std. turning. :- 2 nos.

- VMC machining center Size 1000X800X550 Make BFW with 4th axis :- 5 nos.

- Milling Machine Universal:- 1 nos.

- Radial Drilling machine size 1.5” :- 2 nos.

- Lathe Machines Size 15” Center height:- 6 nos.

- Lathe Machines Size 10” and 12” Center height:- 18 nos.

- Surface Grinding machines outsourced:- 2 nos.

- All the adequate inspection equipment's are in place.

- Setting up of new green sand process state of art Automated foundry unit with installed capacity of 3500 MT per Annum. By Nov,2022

- Increase in Export business 25% share of business.

- Addition of machineries as per the business requirement.

- Up gradation of plant and machinery.

Products

- All

- HEAVY-STATIONARY-ENG

- HYDRAULICS

- INDUSTRIAL EQUIPMENT

- CEMENT-INDUSTRY

- VALVE

- EARTH MOVERS

- WINCHES

- MATRIAL HANDELING

Certification AND AWARD

Valued Customers

New Valued customers under development

Our Address

Email Us

jdpatil@multitechbgm.com

Call Us

+91 9845545473